We Manufacture Constant Pressure Style Motor Brush Holders!

We stock and manufacture replacement brush holders for Baldor-Reliance Electric, General Electric and Westinghouse Electric. We also stock and manufacture other electric motor brush holders such as Metric and European style!

Phone 681-282-5564

Fax 681-282-5565

Email: sales@electricmotorbrushholders.com

Fastest Deliveries in the Industry

Customers Review

Doug-IP Plastics

Tim-CP Industries

Dave-RTA

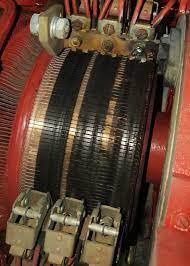

Carbon Brush Holders Play a Crucial Role in the Electric Motor. Here’s why!

The brush holders and springs in your electric motor when cared for correctly, can offer excellent reliability and extend the service life of your electric motor.

The Role of the Electric Motor Brush Holder

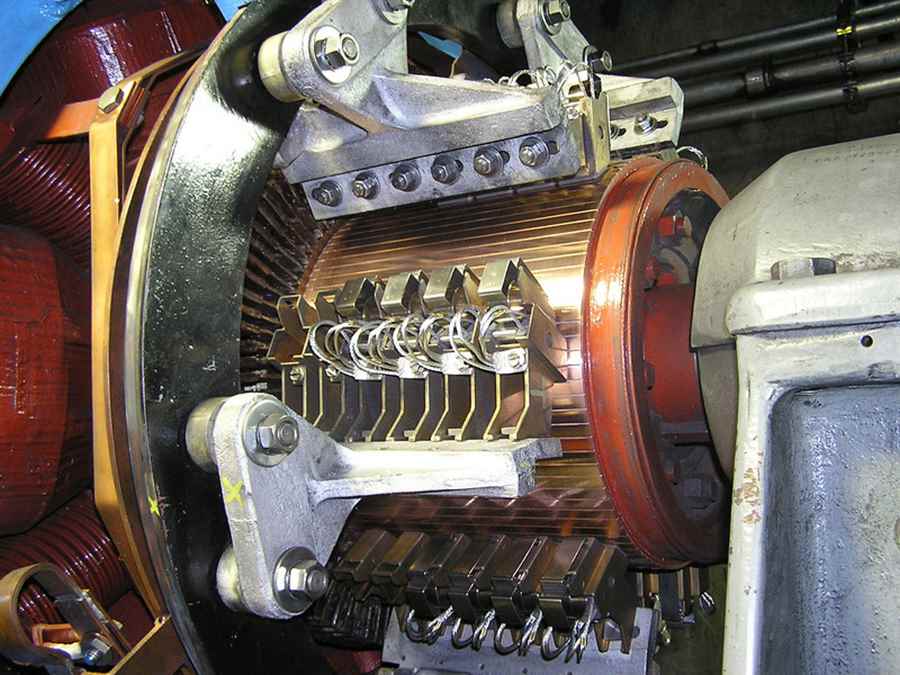

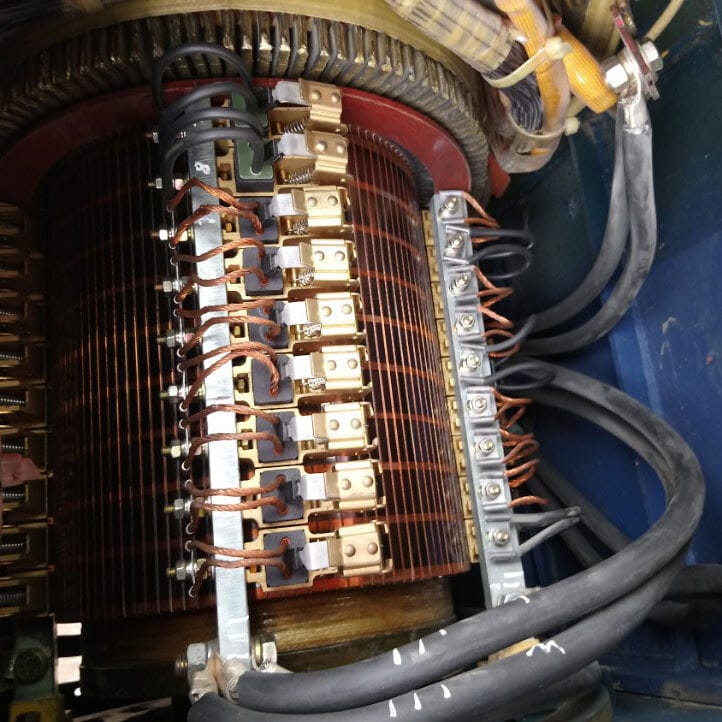

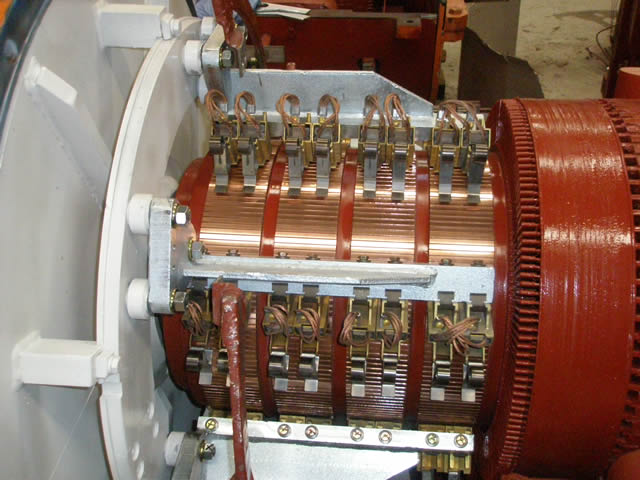

The brush holders are essential parts of an electric motor that provide security and stability to the carbon brushes. Their design and strategic position ensures a firm and secure electrical contact between moving and static parts, thus contributing to the efficiency and durability of the system.

The Role of the Motor Brush Holder Spring

The brush holder spring is used to push the brush down onto the commutator or slip ring in order to maintain an electrical contact to create a magnetic field. The surface of the slip ring or commutator should not be too smooth/glossy or too rough in order to ensure good brush contact and performance.

Laboratory test results indicate that a MINIMUM recommended level of spring pressure for large DC equipment is four pounds per square inch (280 g/cm2). At pressures less than this, the voltage drops and it increases the probability of rapid wear of the brush and contact surface.

Maintenance Practices for Motor Brush Holders and Springs

Just like all parts of an electric motor, brush holders and brush holder springs require regular maintenance to ensure optimal performance. Properly calibrated spring pressure helps manage the wear rate of carbon brushes. Excessive pressure may accelerate wear, leading to premature replacement and potential damage to the commutator or slip ring. Conversely, insufficient pressure can result in poor contact, sparking, and compromised electrical performance. Periodically you should check and clean your holders and springs for contamination.